General

In product development, we work closely with our customers. First and foremost, we want to turn the ideas of our customers into a successful product. The many years of experience with the development of own products is also a great advantage.

In a new development, it is important to consider economic production right from the start. Only if the product can be produced economically, the chance of a successful market launch is given. For this reason, close to cooperate with customers, designers, and pavers is essential.

We are always pleased to help with the further steps of the market launch, which with our excellent network of experienced service providers.

Design

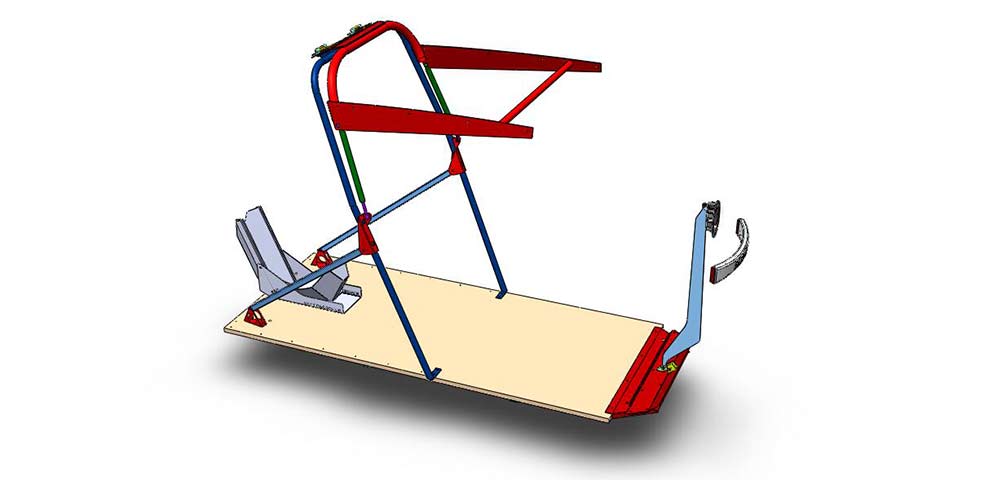

In the first step, the product design is developed with the customer and the designer. Here are included important points such as haptics, application, surfaces and the desired market. The first hand designs help to identify and optimize details and problems at an early stage. Using special CAD software, the designs are converted into a CAD model.

Technology

First and foremost, the technicians focus on the production possibilities and supplement with technical requirements and details in the CAD model, always with a view to economical production possibilities. Manufacturing processes and processes are already considered.

Prototype / Pattern

In this exciting phase, the first prototype or a pattern will be created. Depending on the size, material and purpose of the prototype, it can be produced promptly in 3D printing. 3D printing has become firmly established in product development and enables cost-effective and timely production of the first 1: 1 pattern. It is common to produce prototypes with machining. The advantage of machining lies in the independence of the material selection. Usually, a series of materials can be used here.

Basically, we manufacture models from a wide variety of materials, right through to finishing such as finish, painting, etc. Exhibition exhibits, design models or functional models are implemented exactly according to customer requirements. It is not unusual for us to deliver the model directly to the fair.

Optimization

With the prototypes, initial experiments such as handling, assembly and functions can be depicted. With the help of these experiences, an optimization is then carried out to achieve the series status.

Production

In consultation with the customer, we work out the most favorable production process taking into account various parameters, such as quantity, time of market launch, quality standard, delivery capability, etc. Quality is the prerequisite for a successful product. For your quality assurance, we also design and manufacture testing devices and gauges with practical details.

Projecting - Service - Consulting

From design to serial production, we are your competent partner. With experience and appropriate know-how, we are happy to assist you in the selection of materials, processes and strategies for economical production.